Laser Cutting Services

MetzFab Industries offers comprehensive laser cutting services for short and long production runs. We can offer a full “lights-out” operation to accommodate largest production volumes and turnaround requirements for any business.

Laser cutting is a very-cost-effective method for manufacturing small to medium part orders made from flat sheet metal. With no need for tooling, laser cutting offers quick parts from your CAD file with precision tolerances. Laser cutting is conducted by using a high-powered laser to cut through all types of metals.

Laser cutting produces finished parts and components with smoother surface finishes, and practically burr-free holes and edges while generating less material waste than conventional stamping processes.

We cut most metals, including Stainless steel, aluminum, steel, cooper, brass, and nickel. Our laser cutting technology produces consistently accurate parts with highest edge quality possible across a wide range of materials and sheet thicknesses. We use advanced nesting software, so we can utilize the majority of the raw material and eliminate metal waste, maximizing the value for our customers.

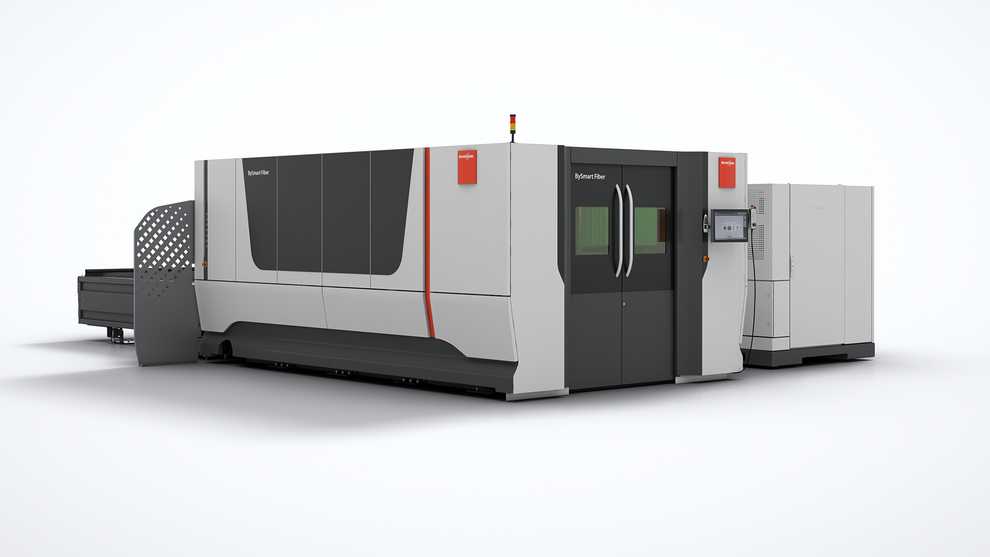

At MetzFab Industries, we have invested in the Bystonic BySmart Fiber 3015 6.0kw & ByTrans Extended fiber laser system. 60” X 120” –

Maximum cutting sheet thickness

- Steel 1.0 inch

- Stainless steel 1.18 inch

- Aluminum 1.18 inch

- Brass 0.59 inch

- Copper 0.47 inch

Industries

MetzFab Industries provides laser cutting services for a broad range of industries, including:

- Construction

- Industrial fabrication / manufacturing

- Military and Defense

- Automotive

- Recreational Vehicles

- OEM

- Agricultural

- Furniture

- Communications/telecom

- Alternative Energy

Additional Services

- Bending

- Tube Services

- Welding

For more information about our laser cutting services, contact us or request a quote.